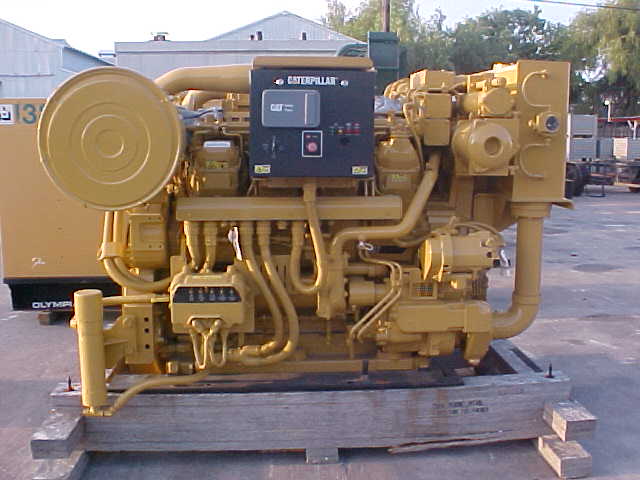

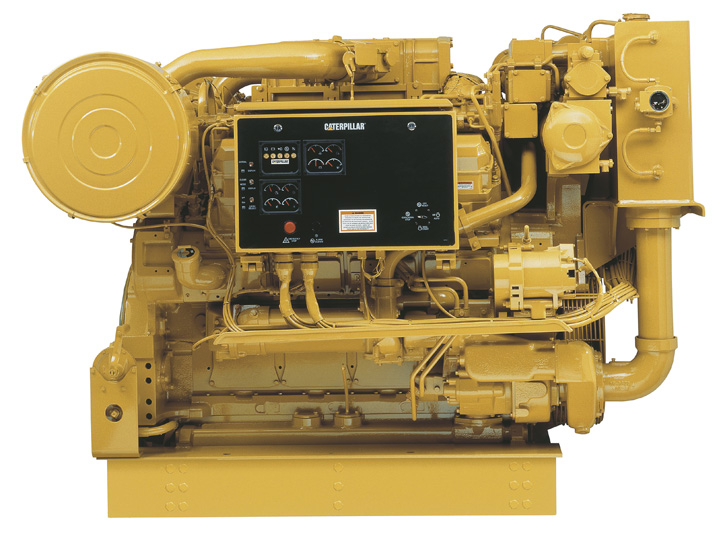

The Caterpillar 3508 Marine engine is widely used in the marines. When on water, compromise could mean a lot of possible injuries and damage so water vessels cannot run on anything but the best engines. This Caterpillar engine is found on a lot of fishing boats, cruise ships, ferries, general cargo boats and other types of water crafts. This and other engines have ISO certification and is built at Caterpillar ISO-certified facilities.

Why the Caterpillar 3508 Marine engine?

This engine has a number of features that make it a most reliable choice. One is the air inlet system that has a corrosion-resistant coated circuit after cooler core. This system also has regular duty air cleaners that have service indicator and dual turbochargers.

The control system is a dual Caterpillar A-111 electric engine control with rigid wiring harness and an electronic unit injection fuel system. The cooling system is utterly reliable thanks to an auxiliary fresh water pump, another non-self-priming pump for sea water, a centrifugal jacket water pump that is gear driven, an engine oil cooler, expansion tank, thermostats as well as housing.

The lube system has a crankcase breather mounted at the top, oil filters at the same position, a rear sump oil pan, a gear type oil pump and gear type scavenge oil pump and RH oil level gauge and oil filler. The mounting system has ledge type mounting rails of engine length and the power take-offs have an accessory drive on lower RH and lower LH with front housing that is two sided.

The engine is well protected with a protection system that has A-111 electronic monitoring system with engine deration strategies that can be programmed. Protection is also assured with an emergency stop push button, protection against over-speeds and there is also safety shut off protection for water temperature and oil pressure.

In the exhaust system, there are dry, gas tight, manifolds that have heat shields that are thermo-laminated. There is also a vertical exhaust outlet, twin turbochargers that have water cooled bearings and thermo-laminated heat shields. The fuel system is fitted with a fuel transfer pump, a RH fuel filter that has service indicators and an electronic unit injector fuel system.

When it comes to instrumentation, the Caterpillar 3508 Marine engine is top of the range. Instruments are mounted on a panel on the engine. They include an alarm horn, an over-speed shut down light indicator, emergency stop light indicator and secondary ECM ready light and active light.

The panel also has a graphical display unit for digital or analog display of system DC voltage, water and exhaust temperatures, speed of the engine, total and instantaneous consumption of fuel, air inlet restriction, fuel and oil pressure, the differentials on the oil and fuel filter, service meter and system DC voltage.

On-going service for on-going performance

This and other Caterpillar products come with ongoing and comprehensive sales and service support. You can always count on the Customer Support programs and maintenance services. You also have the option to have the engine re-manufactured, a number of repair options and you can always get genuine parts to replace worn or old ones.

Sustainability is also assured thanks to a focus on environmental conservation. The manufacturing process of Caterpillar engines and other products abide by global gas emission regulations and recycling of engine parts and office parts is adhered to as much as possible. Any person or organization using Caterpillar products can be sure that they are working with a machine that puts the environment first so they can be sure they are making only sustainable profits and progress.

The Cat 3508 Marine Engine Series Provides Lower Emissions with More Power

A Rating (unrestricted continuous) - For vessels operating at 100% rated load and rated speed without interruption or load cycling.

Common applications include tugboats, freighters and bottom trawlers.

Heavy Duty B ratings - For vessels operating at up to 80% rated load and rated speed with some load cycling (40% to 80% load factor).

Common applications may include mid-water trawlers, crew boats, ferries, towboats and supply boats. Typical operation ranges from 3000 to 5000 hours per year.

Intermittent Duty D Ratings - For vessels operating at rated load and rated speed up to 16% of the time (up to 50% load factor).

Common applications include offshore patrol boats, police boats, some fishing vessels, fire boats, or harbor tugboats. Typical operation ranges from 1000 to 3000 hours per year.

The 3500 Series Meets EPA Tier 2 Marine, EU Stage IIIA and IMO Regulations

The Cat 3508C has ratings for commercial marine applications that meet IMO II and EU Stage IIIA Regulations. The Caterpillar 3508B marine engine has ratings for commercial marine applications that meet IMO I Regulations. Not compliant with current U.S. EPA or EU emissions regulations.

Specs

| Bore - mm (in) | 170.0 (6.69) |

| Stroke - mm (in) | 190, 215 (7.48, 8.46) |

| Rated Speed | 1200, 1600, 1800 rpm |

| Aspiration | Twin Turbocharged-Aftercooled |

| Governor | Electronic |

| Cooling System | Heat Exchanger or Keel Cooled |

| Rotation (from flywheel end) | Clockwise or Counterclockwise |

| Length-mm (in) | 2117.3 (83.3) |

| Width-mm (in) | 1703 (67.1) |

| Height-mm (in) | 1828.9 (72.1) |

Marine Propulsion Ratings

[avia_table]

| MODEL | RATING | RPM | POWER (bhp) | POWER (kW) |

| 3508C | A/B/C | 1200 | 775/850/900 | 578/634/671 |

| 3508C | A/B/C | 1600 | 1000/1050/1100 | 746/783/820 |

Downloadable Documents

Additional Images

Caterpillar 3508 Marine Engine Inventory

-

High Hour Runner Caterpillar 3508B 1000HP Diesel Marine Engine

-

High Hour Runner Caterpillar 3508B 1000HP Diesel Marine Engine

-

New Surplus Caterpillar 3508B 1100HP Tier 1 Diesel Marine Engine

-

Rebuilt Caterpillar 3508B 855HP Tier 1 Diesel Marine Engine

-

Rebuilt Caterpillar 3508C 1050HP Tier 2 Diesel Marine Engine

-

High Hour Runner Caterpillar 3508 DITA 855HP Diesel Marine Engine

-

High Hour Caterpillar 3508B 1050HP Tier 1 Diesel Marine Engine