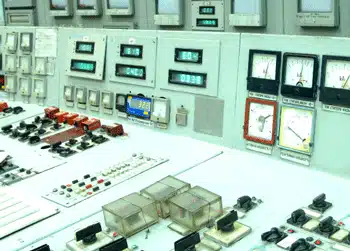

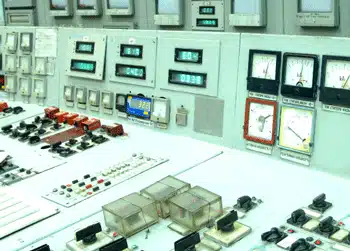

Like any complex machine, industrial generators and engines have user interfaces that allow an operator to monitor its actions, ensure it is functioning efficiently and step in when something goes awry. Even in the best conditions, generators still slow down, speed up, overheat, or malfunction due to a number of potential factors, along with the regular wear and tear of their parts that takes place over time. This means having a reliable interface is necessary for keeping a generator operational as much as possible.

These days, many generators are completely digitally self-managed, while others are less automated and controlled by an analog system. While it might be easy to assume that anything digital will outperform analog, you might be surprised to find that each type has some unique advantages. Here’s why:

Advantages of an Analog Control System

Traditionally, analog control systems are better suited for diesel engines that provide power to smaller appliances, including power generators used as backup power sources for small buildings or facilities. These analog controls are typically integrated into the engines for monitoring their function. The following are some of the advantages of using an analog control system:

- Ease of use – Compared to digital control, operating with an analog system is relatively straightforward. Technicians do not need a very high-level technical background to know how to operate these systems. In the case of generators, analog control systems allow for them to be quickly and easily controlled.

- Environmental tolerance – Unlike their digital counterparts, analog control systems are known for being able to weather a broader range of external conditions. They can still function in hostile work environments (for example, high humidity or large concentrations of dust and debris). On the other hand, you need a reliably clean generator room environment for a digitally controlled generator system to run without frequently encountering problems.

- Lower service and repair costs – When it comes to service and repair, individual meters can be replaced relatively easily, thus rendering analog control systems less expensive. In the case of digital control panels, the entire system may need to be replaced if an error or issue is detected, requiring a large amount of time and effort to re-install and complete the repair – not to mention a hefty fee to pay for the job. Similarly, maintenance costs tend to be higher for digital control systems.

Advantages of a Digital Control System

Digital control systems are particularly useful for mission-critical facilities, which require more complex and uninterrupted back up power and distribution sources. These types of facilities are also characterized by a mix of linear and non-linear load requirements, which make manual adjustments and control options less desirable. Here are a few reasons why digital control systems are beneficial to generator power systems:

- Highly accurate real-time data reporting – Digital control tools are decidedly integrated, reporting the real-time status of all attributes of the diesel engine concerned with superior accuracy – fuel levels, battery status, engine temperatures, etc. A single screen captures a clear picture of the entire system, so the operator monitoring the engine is able to speedily pinpoint and resolve any given issue. In contrast, analog control systems require making physical modifications or substitutions to various resistors and modules when a problem arises. Moreover, engines controlled by analog sets report a failure through general indicator lights or alarms that may not point out a specific issue, making it harder to diagnose the problem.

- Remote access – A digital control system can connect to a remote computer that monitors the machine’s status and progress from a potentially distant location. A single digital master control system integrates all functions of the generator, as opposed to analog controls that have independent control modules for each specific function. As a result, digital control systems save a significant amount of space.

- Greater reliability and efficiency – Because digital control systems typically have built-in redundancy, they allow for continual system function if a part or component of a circuit fails. And since they automatically adjust fuel input rates and injection timing when necessary (depending on the load conditions), digital controls also increase engine efficiency and reduce exhaust emissions. Diesel engines with analog controls that monitor engine speeds actually have a tendency to over-fuel an engine during start up, creating the dark exhaust sometimes associated with diesel engines.

Ultimately, both analog and digital controls have pros and cons depending on your needs. When considering an investment in generator power systems with either one of these control systems, be sure to measure the specs against the unique purpose your gen set will be serving..

If you need help finding the right power system for your next project, don’t hesitate to reach out to Depco’s power experts. We help you power your world with confidence so that you stay up and running. For more tips on this topic and answers to FAQs, feel free to consult our resources page or find more helpful insights on our blog.