When your industrial generator efficiency starts to falter, it’s understandable to feel some panic. After all, whether your generators are used for standby or continuous power, they’re critical to your operation. Selecting, installing, and testing new equipment can often be a lengthy and potentially costly process.

The good news is that many of the initial hints that your generator needs some attention are often maintenance issues that don’t necessarily require new machinery.

Below is a quick rundown of what to look for. Use these best practices to get the most out of your generator’s lifespan and continue to power your world with confidence.

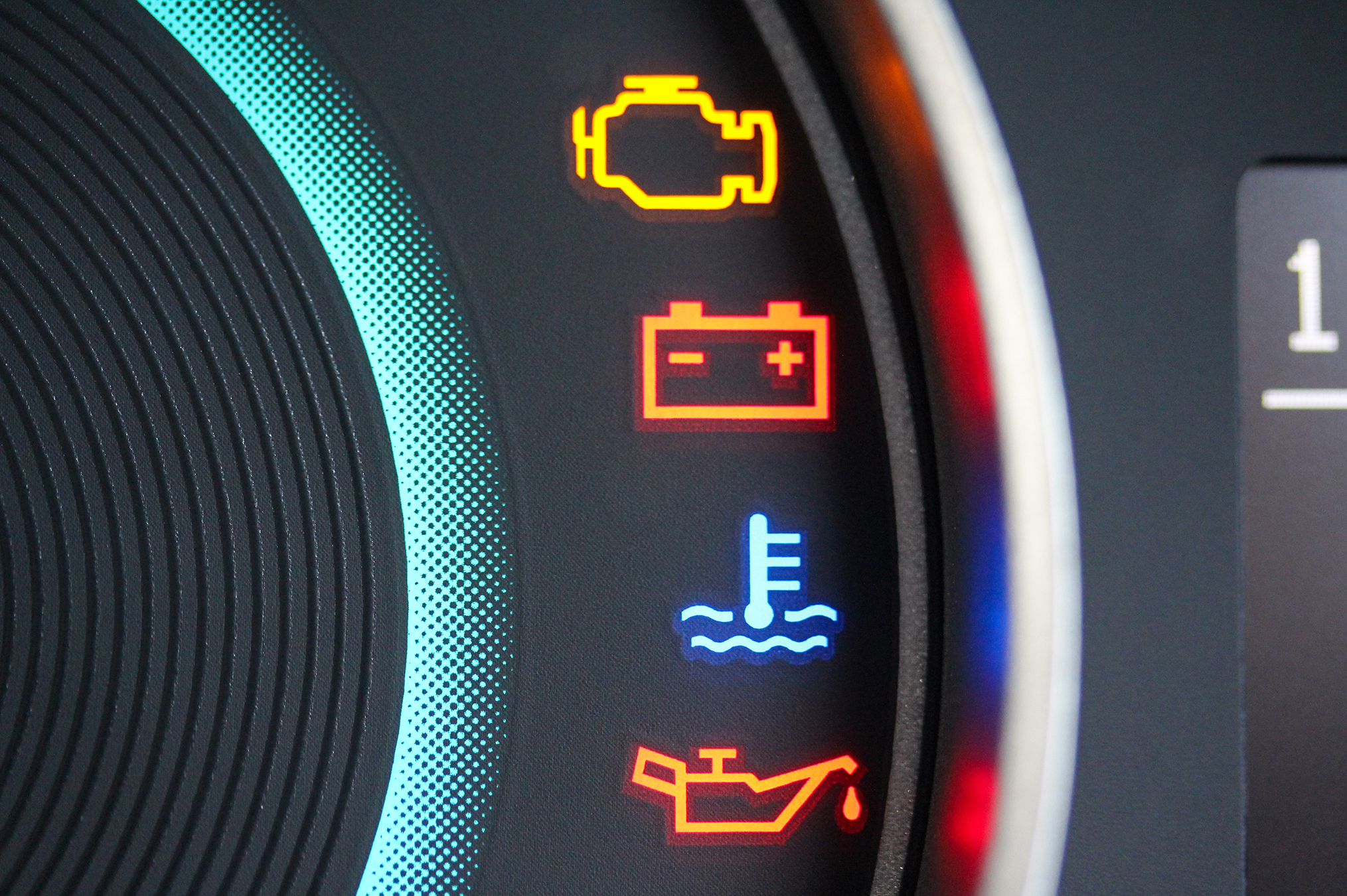

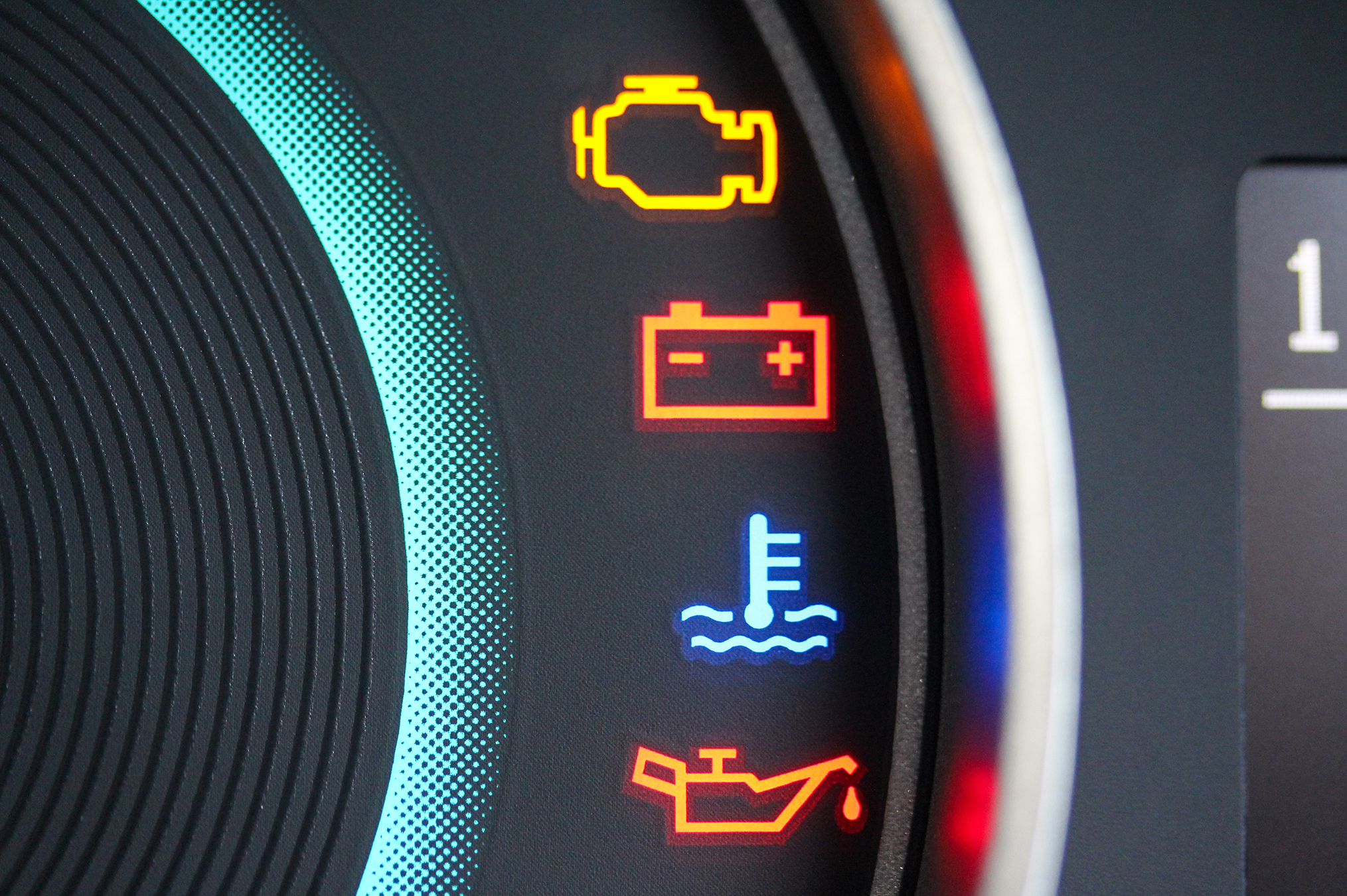

Check the Battery

If you’re seeing signs that your diesel generator’s efficiency is failing, it’s important to remember that the leading cause of power failure symptoms is an issue with the battery. And many times, it’s not even that batteries are dead and need replacing; they may just need to be cleaned.

Because lead sulfates can build up around a battery’s terminals, the residue can limit the current that’s supplied to the power generator. Open or tripped charger breakers, as well as easy-to-fix loose connections, are among the other leading causes of problems limiting diesel generator efficiency.

Diesel Generator Efficiency and Fuel Concerns

If you’re not achieving optimal fuel efficiency, there are a number of ways in which your operation could be impacted.

First, you’re going to be paying more for fuel. Second, you may experience issues handling the load capacity you were counting on. And finally, weak fuel efficiency can be a sign that your generator has larger equipment concerns that, if not addressed sooner than later, can cause much greater system failures.

Fortunately, there are a number of easily fixable factors that could be curbing your diesel generator efficiency. These include:

- fuel leaks

- clogged lines

- oil and filters that need to be replaced

On top of those common issues, certain parts – such as fuel injectors – can experience excessive corrosion and require replacement. One factor that can cause clogged lines and other wear and tear is sludge, which forms due to poor fuel quality.

Oil leaks are caused by what is known as “wet stacking,” which occurs when engines are run well below their expected output and over-fuel the engine, which can create permanent damage. This is why it’s important to right-size your industrial generator according to the power load requirements of your operation. Picking between single-phase and three-phase models is another important decision that could impact your generator’s efficiency.

Losing diesel generator efficiency isn’t all bad news. By performing any necessary maintenance and replacing key parts before the situation deteriorates further, you may save crucial equipment and uptime down the road.

Find Generators You Can Rely On

Depco specializes in supplying industries with reliable power systems that enable their success. Our proven method guarantees quality industrial generators, engines, and more through detailed inspections and repairs.

In the market for a new generator? Download our free buyer’s guide to ensure you get the best fit for your operation. Or, reach out to one of our experts for help finding your next power system.